Fluoropolymers

Thermally and chemically resistant

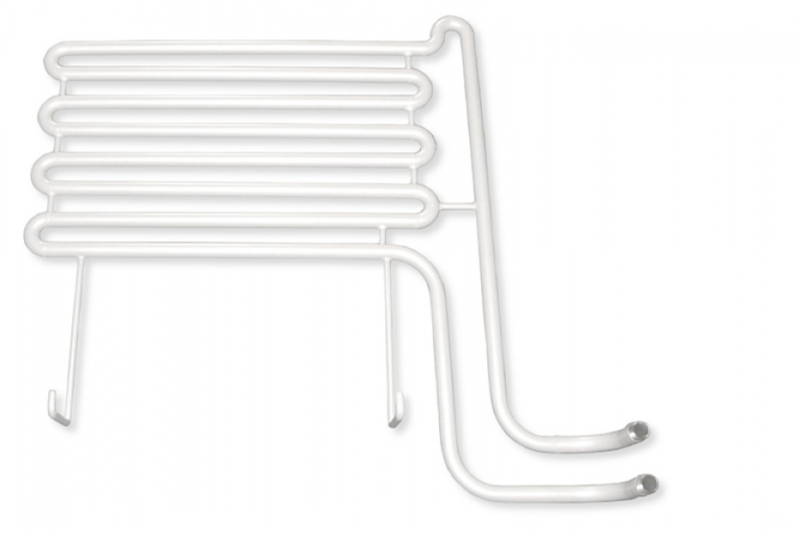

Fluoropolymers is a collective name for coatings from various different manufacturers. Halar® and Xylan® are two examples of coatings that we use at Kersten coating technology. The most widely used fluoropolymers are PTFE, FEP, PFA, ECTFE and ETFE. They present excellent non-stick properties, combined with good chemical resistance. They can also withstand high temperatures. In addition, PFA Ruby Red provides increased resistance to vapour diffusion.

Colours and layer thicknesses

As fluoropolymers are diverse, we use a variety of methods for applying them. For wet lacquering in one, two or three-layer systems, the coating is dried after being applied and cured at temperatures between 200 and 400°C. Fluoropolymers in powder form are applied in one or more layers by electrostatic powder coating on a pre-heated surface. The range of colours depends on the type of fluoropolymer.

Solutions

Sectors

Frequently asked questions

The vapor density of a coating is the degree to which a coating allows vapor to pass through the coating by influence of diffusion. Due to a high temperature gradient across the coating, vapor penetrates through the coating and will condensate on the metal surface. This causes blisters underneath the coating. To counter this, various fluoropolymers have been developed with additives that increase resistance to vapor diffusion.

The following coatings are available in a vapor-tight version:

- Halar®, ECTFE

- ETFE

- PFA Ruby Red

These coatings are mainly used at higher temperatures and in contact with aggressive chemicals.

The following components are used for dry film lubrication: PTFE, graphite and Molybdenum disulphite (MoS2). These products reduce friction so that no oils and fats are required. These coatings are mainly used in clean rooms.

PPG / Whitford's Xylan® coatings are particularly suitable for these applications. However Xylan® is a large family of coatings with different subgroups and specifications. If you wish to receive further information about these subgroups, please contact us !

Friction creates heat and can lead to wear. Low friction resistance means little heat and less wear. These coatings are used in particular at high temperatures, where conventional oils and fats can no longer be used. Or in the foodbusiness in case products need to slide to or into their next position in the process.

Abrasion resistance is the degree to which a coating is resistant to wear. It should be noted that certain coatings are more resistant to abrasive wear than others, but no coating will be able to fully prevent abrasive wear.

Research has shown that thermoplastic coatings in particular are more resistant to wear than epoxy coatings. Thermoplastic coatings are able to withstand the influences of the solid parts much better due to it's flexible nature. Some coatings have a better resistance to wear due to the fact that they can be applied in thicker layers, as there are:

- Rilsan®

- Halar®

- ETFE

- PFA Ruby Red