Rilsan®

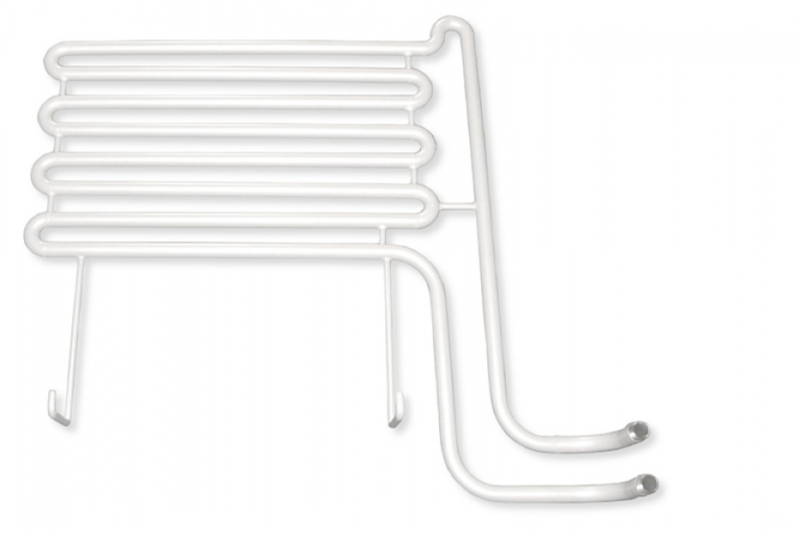

Rilsan® is a powdered thermoplastic plastic coating based on vegetable castor oil. A monomer is extracted from this oil and processed into the polymer nylon 11, or Rilsan®. Coating metal with Rilsan® is an inexpensive and durable alternative to stainless steel. Moreover, this coating complies with the Kiwa Assessment Guideline BRL-K759 and various European directives.

Rilsan®: colors and layer thickness

We apply Rilsan® mainly by swirl sintering, but also by electrostatic powder spraying and rotomoulding. As standard, we coat piping systems with RAL 7001 with a layer thickness of approximately 400 μm. On the outside, the Rilsan® layer can be finished in any RAL color. Small parts can be coated with Rilsan® in white, black and blue. Only one type is available for coating pressure rollers. This variant was specially developed because of its good mechanical and chemical properties and is also applied by the manufacturer.

Solutions

Sectors

Frequently asked questions

Fluidized bed coating is a process in which preheated parts are immersed in a powder bath. This powder is kept in vortex by blowing air through the porous bottom of the bath. This causes the powder to behave as being a liquid. When the blasted and heated part is subsequently immersed in the whirlpool bath, the powder particles melt down as a solid layer.

Both small and large parts can be provided with a coating using a fluidized bed. Especially pipe sections, couplings and fittings are provided with coatings using this technique. Kersten has options to cover parts with a length of 6 meters and a diameter of approximately 1.5 meters within this process

The following coatings are suitable for application by means of fluidized bed coating:

- Rilsan®

- Resicoat®

- Abcite®

Fluidized bed coating has the following advantages:

- Specific parts with difficult-to-access surfaces can be coated easily and in a controlled manner.

- In one operation a layer thickness of 400μm is applied, both internally and externally.

- It is an efficient coating method with very low powder loss.

The UV resistance of a coating is the degree to which it is resistant to, for example, sunlight.

Parts used for production or transport of drinking water must be Kiwa certified. This is applicable for all coatings that are in contact with drinking water during the production process.